Abaqus 6 14 Cracked

Cd Check 3.1.14.0 Serial Numbers. Convert Cd Check 3.1.14.0 trail version to full software.

Mechanical behavior The model is a continuum, plasticity-based, damage model for concrete. It assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material. The evolution of the yield (or failure) surface is controlled by two hardening variables, and, linked to failure mechanisms under tension and compression loading, respectively. We refer to and as tensile and compressive equivalent plastic strains, respectively. The following sections discuss the main assumptions about the mechanical behavior of concrete.

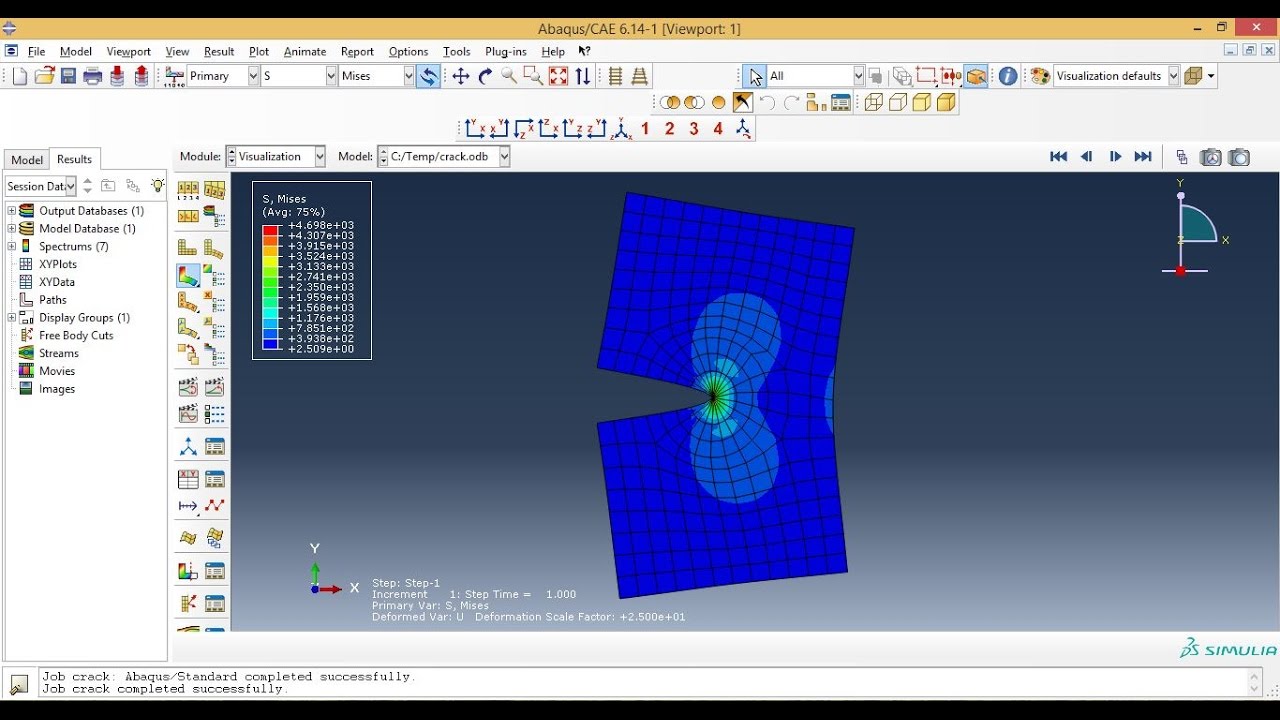

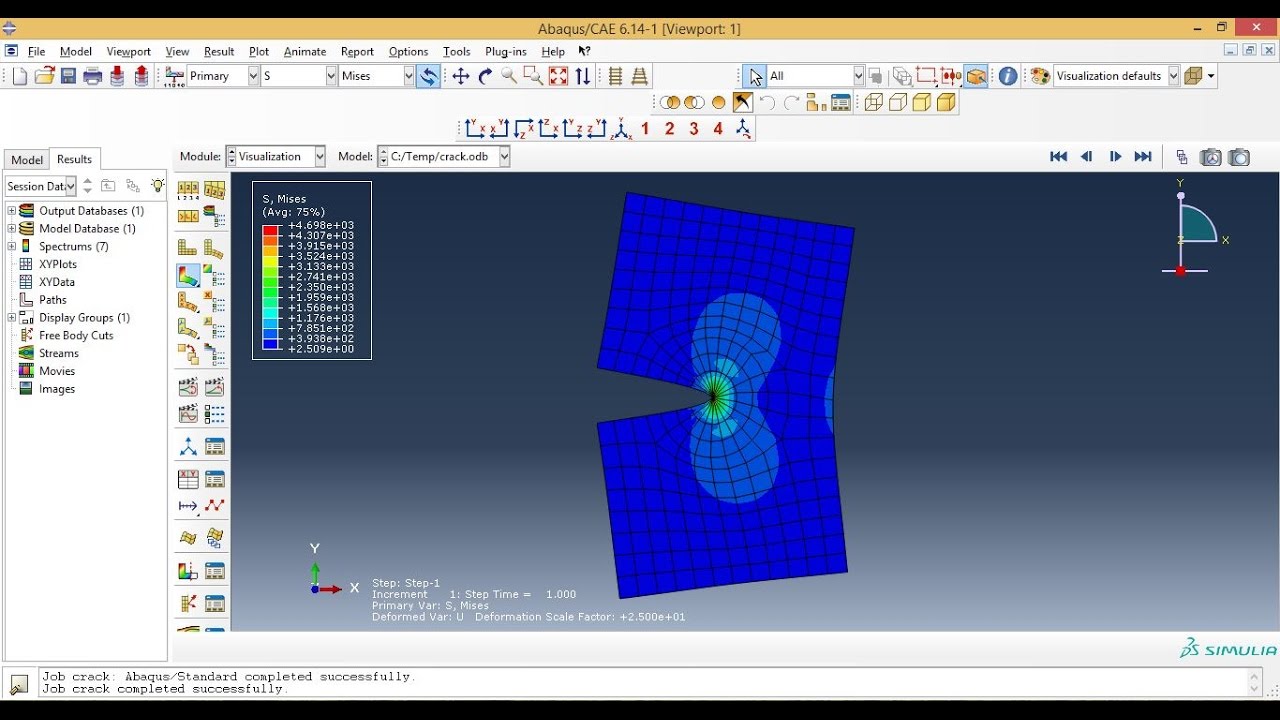

Simulia Abaqus V6.6.3 Download Search Tips Your search for Abaqus 6.14 may return better results if you avoid searching for words like: crack, serial, keygen, activation, code, hack, cracked, etc. 4.5.3 A cracking model for concrete and other brittle materials. The material library in Abaqus also includes a constitutive model for concrete based on. Figure 4.5.3–6 Cracking conditions for Mode II cracking (crack opening dependent model). Using Equation 4.5.3–14, these data are then converted to – data for.

Under uniaxial tension the stress-strain response follows a linear elastic relationship until the value of the failure stress,, is reached. The failure stress corresponds to the onset of micro-cracking in the concrete material. Beyond the failure stress the formation of micro-cracks is represented macroscopically with a softening stress-strain response, which induces strain localization in the concrete structure. Under uniaxial compression the response is linear until the value of initial yield,.

In the plastic regime the response is typically characterized by stress hardening followed by strain softening beyond the ultimate stress,. This representation, although somewhat simplified, captures the main features of the response of concrete. It is assumed that the uniaxial stress-strain curves can be converted into stress versus plastic-strain curves. (This conversion is performed automatically by Abaqus from the user-provided stress versus “inelastic” strain data, as explained below.) Thus. Where the subscripts t and c refer to tension and compression, respectively; and are the equivalent plastic strains, and are the equivalent plastic strain rates, is the temperature, and are other predefined field variables.

As shown in, when the concrete specimen is unloaded from any point on the strain softening branch of the stress-strain curves, the unloading response is weakened: the elastic stiffness of the material appears to be damaged (or degraded). The degradation of the elastic stiffness is characterized by two damage variables, and, which are assumed to be functions of the plastic strains, temperature, and field variables. Uniaxial cyclic behavior Under uniaxial cyclic loading conditions the degradation mechanisms are quite complex, involving the opening and closing of previously formed micro-cracks, as well as their interaction.